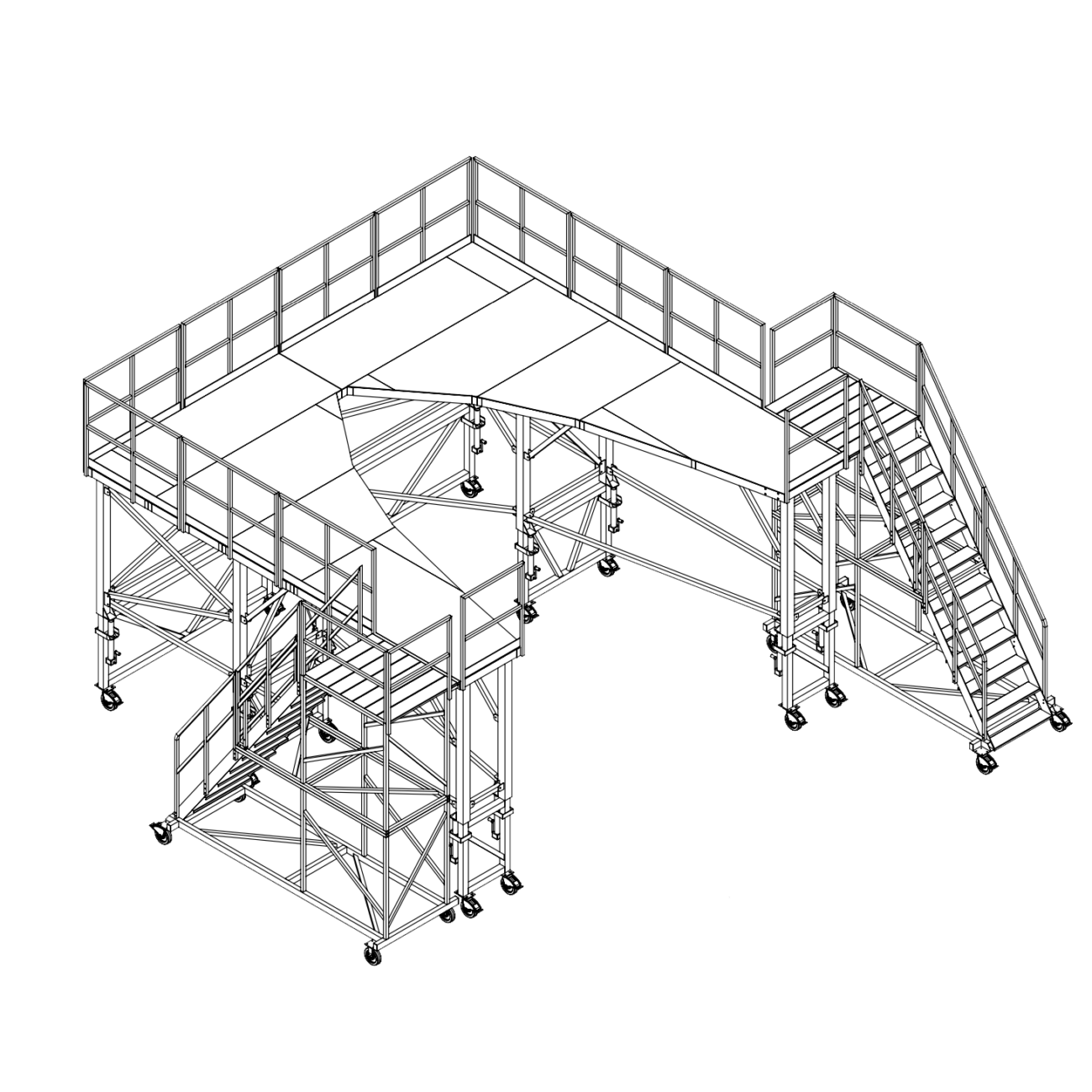

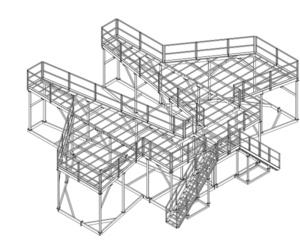

Custom Aircraft Maintenance Platforms

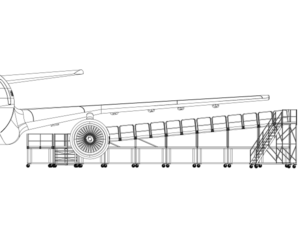

These custom maintenance stands are designed for full applications, for a variety of different aircraft.

As with all our stands, we use anti-fatigue ladder steps rather than narrow ladder rungs. This ensures comfort when using the stands to change LRU’S, adjust components or connect/disconnect engines and nacelles. These stands are currently in use at multiple operators, MRO’S and aircraft manufacturers.

Our defining philosophy, “safety in the air, starts on the ground,” highlights our core focus of keeping our clients and their teams safe.

All Liftsafe products are engineered, designed, built and tested in accordance with OSHA and ANSI regulations.

Many of our products have also been tested and meet or exceed BS EN 131.7, DIN EN 12312-8, EN 1915-1 and include CE certifications.

Designed to be used to service engines, pylons, radome and AFT fuselage points. Our professional engineers can design custom models based on your specific requirements.

Optional telescopic side rails ensure safety compliant access to the forward and AFT lower cargo holds. The aviation wheel well and platform stands are hydraulically actuated.

KEY FEATURES

In-house expertise

We are well-equipped and ready to tackle your custom projects.

Safety First

All our products are designed and built in accordance with industry standards.

Custom design

Custom access products and equipment designed with advanced software.

Innovation

Developed with advanced design software and streamlined processes.

Compliance

Meets and exceeds compliance standards, including ANSI, OSHA and Cal/OSHA.

Customer service

We provide the best experience while meeting and exceeding project expectations

Talk to a specialist today

DOWNLOADS

| Document | Format | Link |

|---|---|---|

| Resource Guide | Download | |

| Aviation Catalogue | Download | |

| Aircraft Access Stand Specification Sheet | Download | |

| Aircraft Maintenance and Engine Access Stand Specification Sheet | Download | |

| Aviation Wheel Well and Platform Stand Specification Sheet | Download | |

| Cabin Interior Access Stand Specification Sheet | Download | |

| Engine Access Slide Scroll Stands Specification Sheet | Download | |

| Landing Gear Access Stand Specification Sheet | Download | |

| Landing Gear Change Stand Specification Sheet | Download | |

| Maintenance Platforms and Docking System Specification Sheet | Download | |

| Nose Cowl Dolly Specification Sheet | Download | |

| Tire Trailers Specification Sheet | Download | |

| Nose Dock Platform (Boeing 787) Manual | Download |

Regulations & Certifications

| OSHA |

| ANSI-ASC A14.7 |

| BS EN 131.7 |

| CE |

| DIN EN 12312-8 |

| EN 1915-1 |

Your Perfect Solution Awaits!

Our process

At Liftsafe, we are focused on collaboration and innovation. Whether you need a custom designed solution, or are simply looking for an “out of the box” product, our process remains laser focused on exceptional service and support.

Phase 1: Design

Every project is unique. In this phase, we take a collaborative and consultative approach to define requirements, evaluate your needs, and explore all possible solutions to ensure the right fit for your operation.

Phase 2: Safety

Our defining philosophy—“safety in the air starts on the ground”—drives our focus on keeping your teams protected. Every solution we develop prioritizes hazard elimination and integrates passive safety features into each design.

Phase 3: Compliance

The aviation sector is one of the most heavily regulated industries in the world. Our staff engineers are up to date on the latest safety regulations and ensure that each piece of equipment meets or exceeds safety compliance standards.

Phase 4: Implement

Each project is launched through a structured process that includes manufacturing, commissioning, and training. Every solution is tested under real-world conditions and refined to meet all design criteria for safe, reliable performance.

Phase 5: Support

Once an aircraft maintenance platform is in service, it faces real-world conditions. That’s why Liftsafe provides ongoing preventative maintenance and service plans to ensure reliable operation and ongoing customer support.

PROJECTS

Custom Nose Dock and Jib Crane System for Aircraft Windshield Replacement

Needing to boost productivity while also keeping the workspace safe, a major Canadian airline teamed up with Liftsafe to craft a solution for safely performing windshield changes on large aircraft.

Engine Access Stand built for B777 Aircraft at Air Canada

Tested and operational at Air Canada; the Engine Access Stand has received exceptional reviews as this aircraft safety solution solved for the clients need to (a) immediately address their safety concerns (b) offer minimal impact to their hangar footprint and (c) could be easily moved/stored by one employee.

Aviation Platform Stand built for 767 and A300 Aircraft

The Aviation Platform Stand was originally engineered and designed to replace the “B” series stands (1 through 7) which were originally designed and produced in the early 1950’s to support the highly classified and state of the art B-52, KC-135 and several other new generation aircraft of the era.

Aircraft Maintenance Stand and Landing Gear Access Stand for Fedex

We were thrilled to be at this FedEx facility recently. Our line of aviation access and safety platforms/ladders provides safe and efficient access to a wide variety of aircraft. Pictured is the Aircraft Maintenance Stand and the Landing Gear Access Stand.

RELATED PRODUCTS

Engine Access Stands

Engine access stands designed with anti-fatigue steps, compact geometry, and reliable functionality.

Aircraft Tooling

Aircraft tooling designed for efficient handling and interior access, including service carts, dollies, and ladders

Aviation Engineered Solutions

Engineered solutions for the aviation industry, designed and built in-house by expert engineering and fabrication teams.