Column Mounted Truck Netting Systems

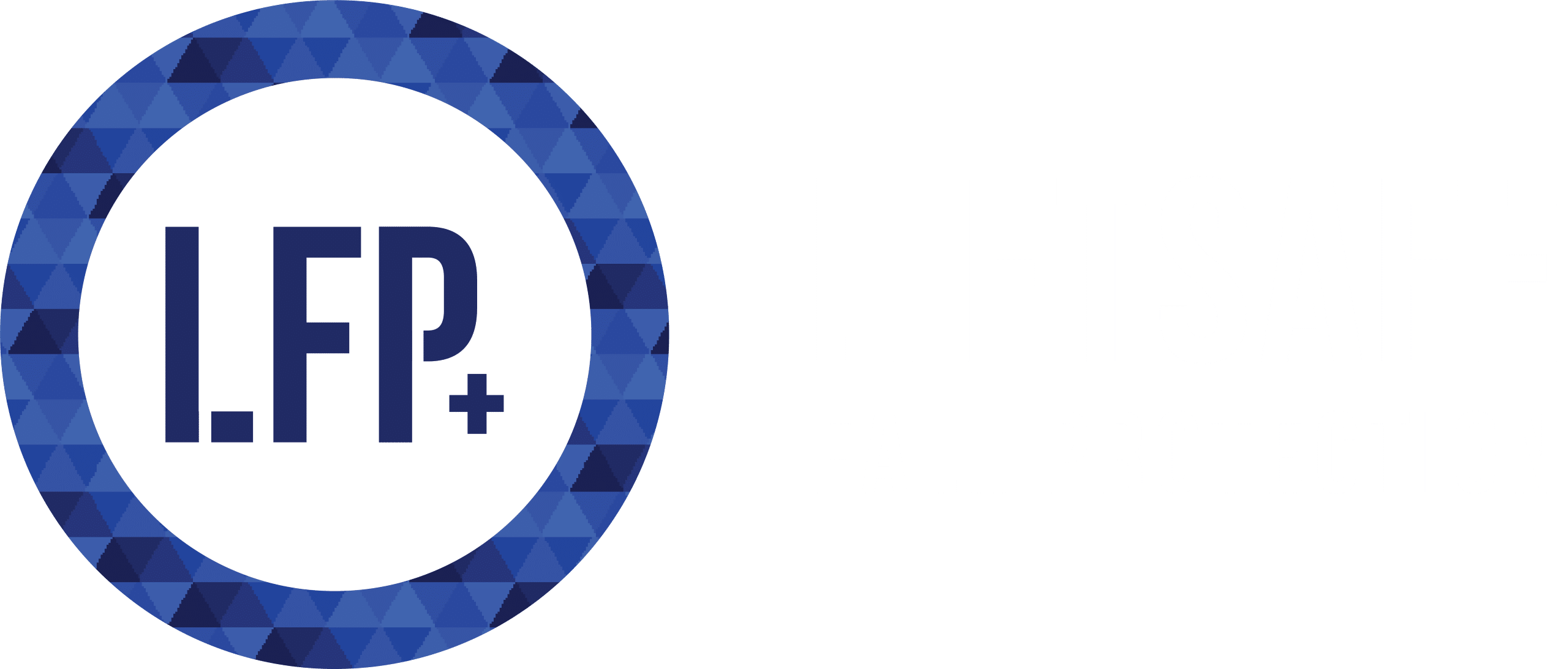

Classic Column Mount Truck Netting System

Components

- 3 column mount brackets (consist of 2 plates)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- Stake pockets for every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

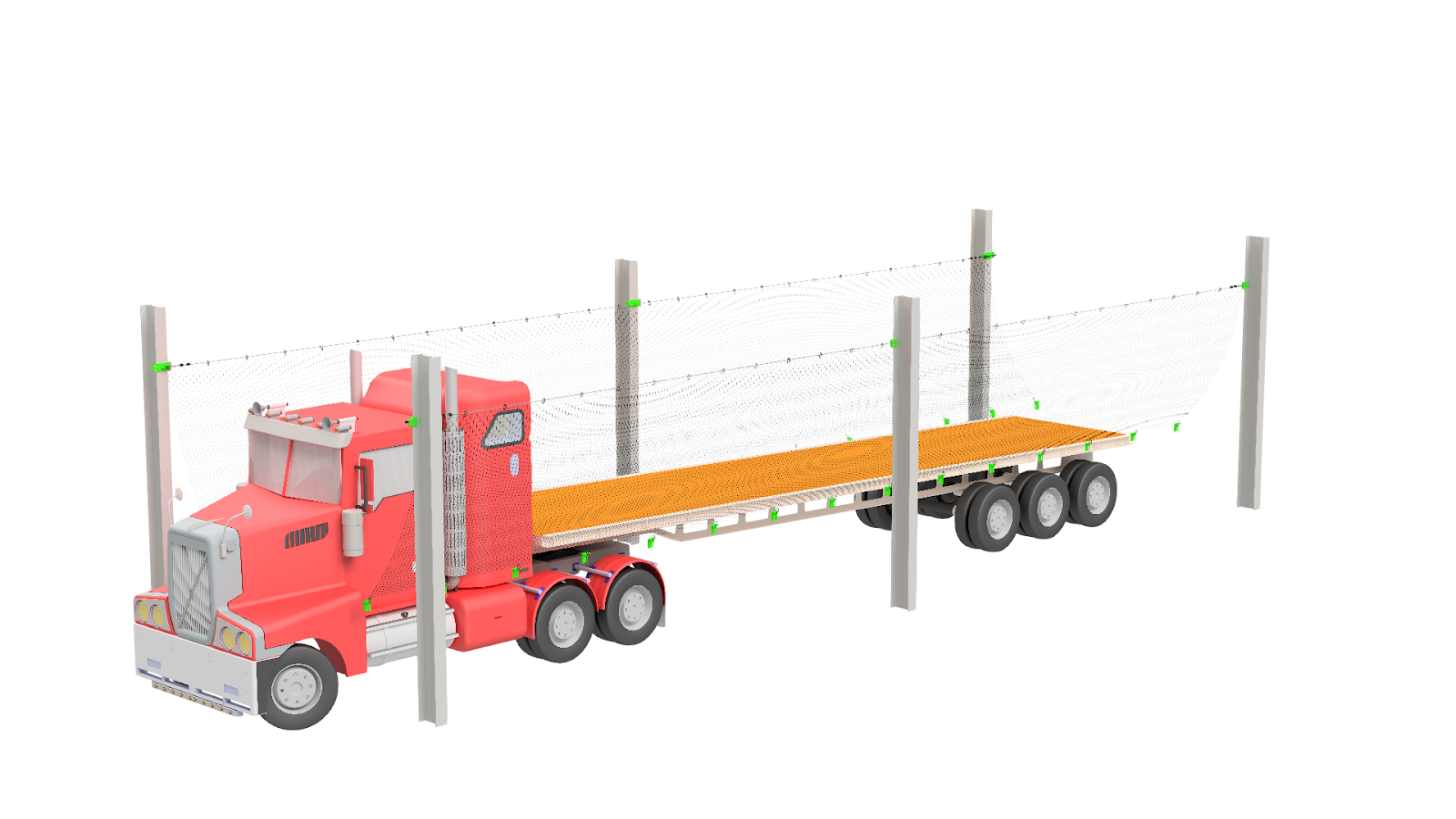

Flange Mount Truck Netting System

Components

- 3 flange mount brackets (consist of 3 plates)

- 3/8-inch galvanized GAC

- Snap hooks for every 2 ft

- Stake pockets every 2 ft

- 2 3/8-inch light duty thimble

- 1 net panel

- 4 3/8-inch wire rope clips

- 1 TB (6-inch x half inch)

- Bases: 4000 lbs (2 tons per base)

- Custom net sizes based on each project

- Material: 3000 lbs net – nylon

- Knotless netting, sewn rope border

- U.V. protection

- Net colour: black

- Fire rated (FR) (NFP 701)

- Load rated netting panels

- Engineered offset brackets

- Customized solutions available

- Easy and simple to use

- Custom configurations available

- Hybrid system options available

- Built to fit your location

- Solve for liability concerns

- Safety solutions for workers

Flatbed trucks

Netting panels are treated to meet NFPA 701 standards for fire-retardancy and have been tested and rated in accordance with ANSI A10.11 and OSHA safety standards.

View our complete product selection:

Frequently Asked Questions

Passive vs Active fall protection?

Passive fall protection does NOT require any action by people. Examples include: Guardrails, Safety Nets, etc. Active fall protection requires training and direct connection to an engineered fall protection system or anchor point. Examples include: Body Harnesses and Lanyards, Anchor Points, etc.

What are the regulations i need to know?

OSHA 12.10 (1.1), every employer shall provide a fall-protection system to any person, other than an employee who is installing or removing a fall-protection system in accordance with the instructions referred to in subsection (5), who works: (a) from an unguarded structure or on a vehicle, at a height of more than 2.4 m above the nearest permanent safe level; (b) from a temporary structure at a height of more than 6 m above a permanent safe level.

ANSI A10.11 All nets supplied are manufactured and tested in accordance with Industry Standards, and all such netting has been tested to strict ANSI standards as laid out in ANSI A10.11. This includes the complete system with all hardware installed onto a racking system and tests made to simulate a real-case product fall.

Is this something I could install on my own?

Yes, all of our systems include a user manual, custom drawing, and detailed installation instructions. If needed, we offer installation services.

Untested and/or self-fabricated remedies are risky. You are responsible for any accidents relating to the failure of hardware and installation. Incorrect installation could result in a system that does not provide the protection you require.

When would I need truck netting?

Netting is used anytime a fall hazard may exist. It is used to protect workers when performing a job on or around a parked flatbed truck.

What do I need to provide to get a quote?

Get in touch with our sales reps, and they can provide you with a Quote Request Form that is easy to fill out. The form asks for information such as the width of your bays, the height of your rack frames, and the weight of the pallets you are looking to protect.

Things to consider

The amount of space available beside the “typical” trailer location when loading/tarping/etc.

The further away from the trailer you can position the posts, the lower the posts have to be.

Overhead cranes. Do they load from the side, the end or both? If from the side, how high can the posts be without interfering with the loading process?

Connection to the trailer – the standard system requires attachment directly to the trailer while the pivot system does not.

Forklift loading from the side – is this done at all? If so, the trailer safety nets will not work.

Request a Quote

Industrial Barrier Netting

Engineered vertical barrier netting systems around stacked boxes and walkways to provide protection against falling materials and a security barrier against potential theft.

Roofguard Rooftop Guardrail

Modular rooftop guardrail systems designed to protect employees working at, or near, the leading edge while working at heights.

RackGuard Netting Systems

RackGuard netting is a cost-effective, engineered solution designed to make warehouses and industrial racking safer for employees and visitors by creating a “soft-catch” for products that fall from racking.

Related Products

About Liftsafe Fall Protection

Netting Catalogue

Customer Service

Request a quote

We offer a huge selection of products and quick quotes for what you’re looking for.