Aircraft Nose Cowl Dollies

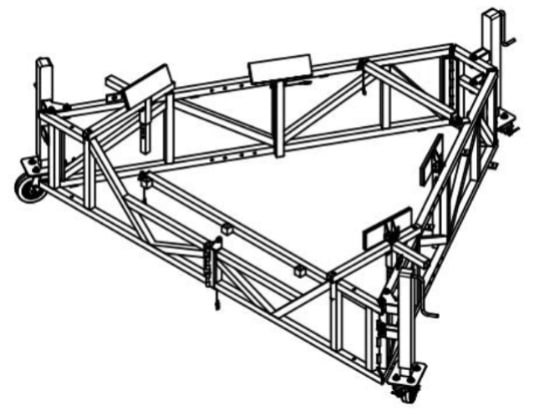

The Aircraft Nose Cowl Dolly is a new and innovative solution designed to enable the safe removal and installation of aircraft nose cowls without the need for an overhead crane. This unit offers a ready-to-ship AOG configuration, featuring a lightweight and compact design for efficient storage and transport.

Engineered for versatility, the Nose Cowl Dolly is capable of handling nose cowls across a variety of aircraft engine types and models, providing a secure and stable support platform during installation and removal. The unit’s low-profile structure and ergonomic layout improve safety and accessibility while reducing downtime during maintenance operations.

Constructed with high-strength materials and a corrosion-resistant finish, the dolly ensures long-term durability in demanding maintenance environments. Its adjustable cradle system and lockable swivel casters allow precise alignment and controlled maneuverability around the aircraft.

Liftsafe’s Professional Engineers can design custom configurations to suit your operational needs, including cradle adjustments, engine type compatibility, and shop layout requirements. Whether used in commercial, defense, or private aviation environments, the Aircraft Nose Cowl Dolly provides a reliable and efficient solution for nose cowl handling and maintenance.

KEY FEATURES

Full Fall Restraint

Integrated fall protection to keep technicians secure during maintenance.

Safety First

Professionally designed to ensure safe and reliable operation.

Multi-Functional Design

Adaptable platform configuration for a wide range of aircraft tasks.

Custom Solutions

Tailored to meet specific operational and aircraft requirements.

Safe Maintenance Access

Provides secure and stable access to inspection and service areas.

Compliance

Engineered and tested to meet all aviation and workplace safety regualtions.

Durable Construction

Built from high-strength materials for demanding aviation environments.

Warranty Support

Available warranty options for long-term performance assurance.

Talk to a specialist today

Specifications

| Specification | Details |

|---|---|

| Model # | DF071560-01 |

| Application | Nose Cowl Removal & Installation |

| Movement | 1 person |

| Footprint | 84″ x 107 3/4″ x 84 1/2″ / 213.3cm x 273.6cm x 214.6cm |

| Shipping (DIMS) | 17 9/16″ x 27 1/2″ x 95 1/8″ x 150lbs / 44.6cm x 69.8cm x 241.6cm x 68kg |

| Height | Variable |

| Certifications |

ANSI-ASC A14.7 BS EN 131.7 CE |

| Material | Aluminum |

| Finish | Powder Coated Finish |

| Caster Details | 8″ / 20.3cm Split Castor with Brake and Swivel Lock |

| Padding Material | Anti-Marking Retention Pads |

Regulations & Certifications

| OSHA |

| ANSI |

| BS EN 131.7 |

| CE |

| DIN EN 12312-8 |

| EN 1915-1 |

Your Perfect Solution Awaits!

PROJECTS

Custom Nose Dock and Jib Crane System for Aircraft Windshield Replacement

Needing to boost productivity while also keeping the workspace safe, a major Canadian airline teamed up with Liftsafe to craft a solution for safely performing windshield changes on large aircraft.

Engine Access Stand built for B777 Aircraft at Air Canada

Tested and operational at Air Canada; the Engine Access Stand has received exceptional reviews as this aircraft safety solution solved for the clients need to (a) immediately address their safety concerns (b) offer minimal impact to their hangar footprint and (c) could be easily moved/stored by one employee.

Aviation Platform Stand built for 767 and A300 Aircraft

The Aviation Platform Stand was originally engineered and designed to replace the “B” series stands (1 through 7) which were originally designed and produced in the early 1950’s to support the highly classified and state of the art B-52, KC-135 and several other new generation aircraft of the era.

Aircraft Maintenance Stand and Landing Gear Access Stand for Fedex

We were thrilled to be at this FedEx facility recently. Our line of aviation access and safety platforms/ladders provides safe and efficient access to a wide variety of aircraft. Pictured is the Aircraft Maintenance Stand and the Landing Gear Access Stand.

RELATED PRODUCTS

Engine

Access Stands

Engine access stands designed with anti-fatigue steps, compact geometry, and reliable functionality.

Wheel and Brake

Service Carts

Durable, low-profile carts designed for safe, efficient transport and storage of aircraft wheels, brakes, and tools.

AIRCRAFT

MAINTENANCE ACCESS

Custom-engineered platforms and ladders designed to provide safe, reliable access to hard-to-reach areas.