Related: Fall Arrest Inspections & Fall Arrest Systems

Related: Fall Arrest Inspections & Fall Arrest Systems

Before we start let us define what fall arrest systems are. Essentially a fall arrest system can be anything that helps prevent you from falling, which is a pretty large umbrella, which is why they are broken down into several different subcategories.

Categories:

Class 1: This class includes body belts; these are designed to restrain a person who is placed in a hazardous work position and reduces the possibility of falling. Please Note: effective January 1, 1998, body belts in the United States are no longer considered to be an acceptable part of a personal fall arrest system.

Class 2: These systems include chest harnesses, which will help to limit the fall hazard, but will not protect you from a vertical free fall.

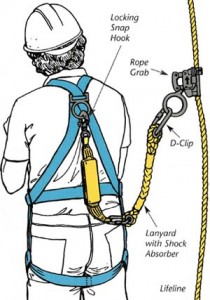

Class 3: Full body harnesses, are designed to be used to prevent the most severe of free falls.

Class 4: Suspension belts, these are used for independent work supports and are used to suspend a worker.

Rope Lanyard: These systems offer some elastic properties for many different types of fall arrests, and are mainly used for restraint purposes.

Web Lanyard: These are ideal for restraint purposes when the potential fall hazard is less than 2 feet.

Cable Positioning: These must be used paired with a shock-absorbing device, but they are perfect for corrosive or excess heat environments.

Shock Absorbers: These are used to reduce the amount of fall arresting force if a fall should occur.

Rope Grabs: These are deceleration devices, which travel on a lifeline and are used to allow for ascension or descend on ladders or slop surfaces and they automatically engage the lifeline and locks, which helps to prevent an employee from falling should they slip.

Retractable Lifeline Systems: These systems give fall protection and mobility to the user when they are working at heights, but require mobility to work.

Safety Nets: These systems can be used to lessen the fall exposure when you are working on temporary floors/scaffolds.

Rail System: These systems can be on a fixed ladder or any curved surfaces and are considered to be one of the most reliable methods of fall protection.

Now that we have defined the different types of fall arrest systems let us move on to how you can maintain and inspect your system.

Harness Inspections:

The following areas NEED to be checked during a harness inspection

Belts and Rings

Tongue Buckle

Friction Buckle

The inspector and designated competent worker will check for frayed edges, broken fibres, pulled stitches, chemical damage, checking for any distortion of the buckles, ensuring the rivets are tight and ensuring the bars on the buckles are straight.

Harness inspections should be completed frequently by the users of the equipment and annually by a certified inspector. If any signs of wear and tear become apparent the harness should be replaced immediately.

Lanyard Inspection:

Like harnesses lanyards should be inspected by a competent person frequently and inspected annually by a certified inspector.

The snaps should be looked at closely for hook and eye distortion, cracks, or pitted surfaces. The thimble or the protective plastic sleeve should be firmly seated in the eye of the splice and should have no loose or cut strands.

Steel Lanyards: During frequent inspections, the inspector should rotate the lanyard and look for cuts, frayed areas or any unusual wear patterns on the wire.

Web Lanyard: The competent person will during frequent inspections bend the webbing over a piece of pipe; look at each side of the lanyard. This will show any cuts or breaks in the lanyard.

Shock-Absorbing Packs: During a frequent inspection the external portion of the shock-absorbing pack should be checked for any burn holes or tears. The area around the D-ring, belt or lanyard should also be checked for any loose strands, rips or deterioration of any kind.

Lifeline Inspection:

Check to ensure the fibre rope lifelines show no signs of fraying, burns, kinking, cuts or any signs of wear and tear. For retractable block lifelines ensure you check the retractable block for smooth operation. This can be done by pulling out the line and jerking it suddenly, which should cause an immediate breaking action.

Maintenance:

To extend the life of your fall arrest system try and keep this in mind for Nylon and Polyester materials; wipe off any surface dirt with a wet sponge, then squeeze the sponge dry and dip it in a mild solution of water and soap. Proceed to wipe the surface repeatedly, once you have created a lather wipe the product dry with a clean cloth and hang it freely to dry (but keep it away from any excessive heat which could cause the item to shrink).

It is extremely important to ensure that not only your employees are regularly inspecting your fall arrest equipment, but also that you get a certified inspector to check your equipment annually. If you do not check your fall arrest systems then damages and flaws could go unnoticed as people use the device, which could cause someone to get hurt or worse. The Canadian Criminal Code Section 217.1, Bill C 45 clearly states that if management does not ensure that these inspections are being completed, and then they risk fines and possible criminal penalties including jail time. So for the safety of your employees and you please make sure your fall arrest devices are being properly inspected and maintained.

Have you ever used a fall arrest harness?

Have you ever worried about the safety of your fall arrest device?

Share your thoughts and feelings in the comment section below!

Sources:

Fall Protection. (n.d.). Retrieved February 23, 2016, from https://www.osha.gov/Region7/fallprotection/fall_protection_info.html

1 (n.d.). Fall Protection: Approvals and Inspections. Retrieved from https://www.ihsa.ca/pdfs/safety_talks/fall_protection_approvals_inspection.pdf