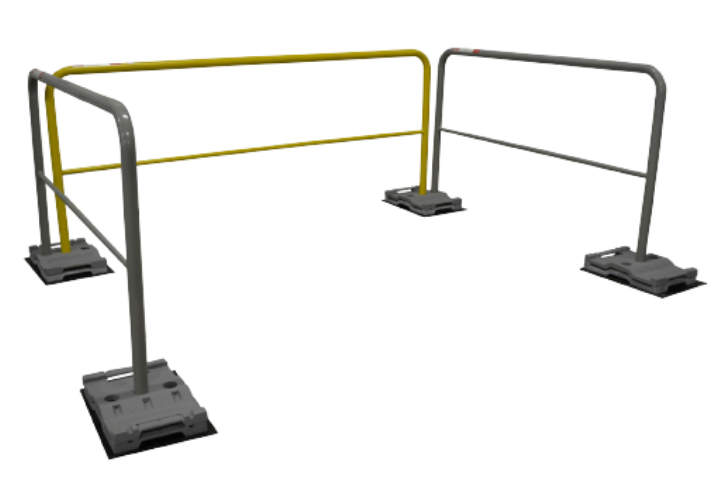

XPress Guardrail Series (RoofGuard)

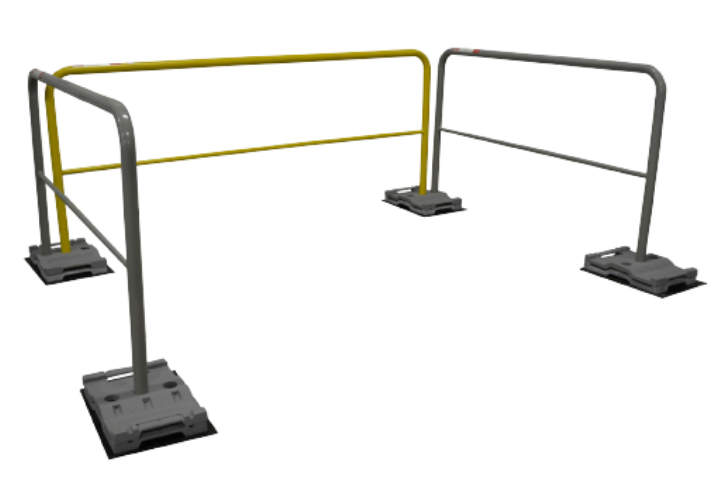

RoofGuard X-Press is a unique, easy-to-install rooftop guardrail system. This rooftop fall protection system is designed with pre-fabricated rail sections that can be installed and dismantled quickly for temporary applications without sacrificing quality, durability, and most importantly, safety.

This one-of-a-kind rooftop guardrail system allows you to create your own rooftop guardrail solution, allowing you to choose how much linear coverage you want to cover, from 8 feet to more than 100 feet and longer.

RoofGuard X-Press comes in two distinct rail lengths; the 8-foot rail length is powder coated in high-visibility safety yellow, and the 6-foot rail sections are powder coated in grey. The 8-foot lengths are designed to go on the roof’s leading edge, and the 6-foot guardrail sections are for the returns. The yellow guardrail also serves as a warning sign for workers who get too close to the roof edge, allowing them to always be aware of potential danger.

Just like with all of our RoofGuard products, RoofGuard X-Press uses a counterweight system, which involves no cutting into the existing rooftop surface. The railing thus has no direct or permanent attachment to your roof, meaning no holes and no leaks!

RoofGuard X-Press has been designed to meet or exceed all major North American safety standards/regulations including Ontario MOL requirements, ANSI, OSHA, Canadian OHS & WorkSafeBC.

Death of worker results in $100,000 fine for Ontario Company

A company pleaded guilty to failing to ensure workplace safety standards were met, as outlined in the Ontario Occupational Health and Safety Act.

Companies are required to protect their workers with a guardrail system or another fall prevention method.

The Ontario man succumbed to his injuries and passed away less than two weeks later.

Do the right thing; protect your employees/company with a passive fall protection system.

Reasons Why You Need RoofGuard X-Press

RoofGuard X-Press Ordering Tips

Your Perfect Solution Awaits!

- Yellow pre-assembled guardrail

- Grey pre-assembled guardrail

- Rubber pads

- Fasteners: stainless steel

- Provides site-specific coverage

- Quick and easy installation

- Modular design for fast, easy assembly

- Custom sizes are available for non-standard skylights

- Meets or exceeds all North American and EU safety regulations

- Available in both kit and custom configurations

- Galvanized finish is corrosion resistant aluminum

- Requires NO penetration of the roof membrane, therefore no risk of leaks

- Counter weighted system utilizing cast steel baseplates to provide enough weight on the “returns” to meet all requirements of lateral force loading

- “Passive” fall protection system

- Provides site-specific coverage (i.e. single HVAC unit) or provides full or partial perimeter coverage on a rooftop

- Durable steel construction

- 1.9″ OD handrail pipe

- Minimal tools required for assembly

- Custom colours available to match existing structure

- Extra heights available for moderately elevated work near an edge.

- Self-weighted bases are portable and allow simple, non-penetrating installation to the rooftop.

- Fixed base sockets are also available for bolt-on applications

- Rail Lengths are 6′ and 8′

- Commercial and residential

- Manufacturing

- Municipal and educational

- Industrial

- Membrane roof

- Ballast roof

- Metal roof

- Flat or low slope roofs

This system is designed to meet or exceed all major governing bodies fall protection requirements Including:

- Canada Labour Code: OH&S – Part 1.S2.5 (1)

- Canada Labour Code: OH&S – Part 12 S 12.07 (1)(2)(a)

- Canada Labour Code: OH&S – Part 12 S 12.07 (1)(2)(b)

- Canada Labour Code: OH&S – Part 12 S 12.07 (1)(2)(c)

See a full listing of our RoofGuard Rooftop Guardrail product line.

Frequently Asked Questions

When is fall protection required?

Employers must provide protection to prevent employees from falling. According to Canadian Centre for Occupational Health and Safety (CCOHS) laws, any surface 3 metres (10 feet) above another level requires fall protection. In most cases, fall protection is required when:

- other means of fall protection are not available or possible, such as guardrails

- working at a height of 3 metres or more (permanent and/or temporary work areas)

- working at a height of less than 3 metres when the surface below could cause a greater injury than just the fall (e.g., machinery; risk of drowning in water or other liquid; open tanks, vats, or pits containing hazardous materials; materials that can shift)

- a worker may fall through an opening in the work surface

- it is determined that fall protection is necessary

I don’t know if I need a rooftop guardrail system. Can Liftsafe Fall Protection help me decide?

For sure! Fall protection regulations can be tricky, so if you’re unsure whether a rooftop guardrail system is the right solution, we can help. Just click here to fill out the form with as much detail as possible and our team will get back to you as soon as possible for a complete consultation. You can also reach our team directly at:

Phone: 1-800-977-2005

Email: info@liftsafegroup.com

Do RoofGuard Guardrail Systems comply with current US/Canada safety regulations?

What is the difference between active and passive fall protection?

Both active and passive fall protection are effective in protecting workers from falling. However, while active protection requires involvement from the worker, passive systems can keep people safe regardless of training level and awareness of a hazard.

Active fall protection are known as Personal Fall Arrest Systems (PFAS), such as body harnesses, lanyards, and anchor points. Passive fall protection, alternatively, are physical barriers or systems, such as guardrails and safety nets, that prevent workers from falling or catch them if they do fall.

Passive solutions are always preferred to active ones. They represent engineering controls that keep people safe regardless of training level and awareness of a hazard.

How can I purchase RoofGuard Guardrail Systems from Liftsafe Fall Protection?

It’s pretty simple. Click here to request a quote and our team will get back to you as soon as possible. Don’t forget to fill out the form with as much detail as possible so we can provide a precise quote. You can also reach our team directly at:

Phone: 1-800-977-2005

Email: info@liftsafegroup.com

How long does it take to install a rooftop guardrail? Does it require any special tools or skills?

Roofguard is incredibly simple to install and can be easily installed by an inexperienced worker with simple hand tools and our instructions. Each system has labels that contain a QR code linking to a series of videos showing exactly how to install it for maximum time savings.

Are RoofGuard Guardrail Systems certified by an engineer?

Each RoofGuard system comes with a stamped engineering drawing back by the in-house engineering team at Liftsafe Fall Protection.

Are guardrails more expensive than horizontal lifeline systems?

While every system is different, at times the initial costs of guardrail can be slightly more compared to horizontal lifeline systems. However, you also need to consider the costs of certifying employees for working at heights (every three years), anchor point inspections (annually), lanyard and harness costs and inspections (annually), recordkeeping (ongoing), a rescue plan, and other related costs. When you take these into account, the overall cost of an installed guardrail system is much lower when compared to horizontal lifeline systems.

There is also the amount of time and resources that must be devoted to making sure these are all adhered to. Whereas, a guardrail system can be set up once and you are instantly compliant.

Are the materials used in the RoofGuard Guardrail Systems protected from corrosion and other environmental factors?

Yes. RoofGuard Guardrail Systems are typically made of aluminum, which ensure durability in diverse weather conditions. They are designed to be protected from corrosion, rust and other environmental factors, and its components contribute to resistance to environmental wear and tear.

How does the RoofGuard Guardrail stay in place if it isn't secured to the roof?

The RoofGuard Guardrail System is a modular, non-penetrating system designed to eliminate the potential hazard of falls over unprotected edges on a rooftop or elevated surface. It is counter weighted, which means it requires no welding, drilling, or bolting into the actual roof structure, and is designed to rest on top of it while still meeting lateral force requirements set out in the appropriate standards and laws.

Can RoofGuard Guardrail Systems be painted?

Yes. RoofGuard comes standard as an aluminum system that is grey but some clients prefer it to be painted safety yellow. This is done in-house with a powder coated paint that is weather resistant.

Can RoofGuard Guardrail Systems be used as an anchor?

No. RoofGuard must not be used as an anchor. This is stated explicitly in the RoofGuard installation manual among other safety requirements.

Can RoofGuard Guardrail Systems be installed on a sloped roof?

Yes. This depends on how steep the slope is for standard systems (it must meet the standards and regulations for sloped roofs). However, custom systems are available for multiple applications including sloped roofs.

Why our Fall Prevention Systems are Right for You

All of the RoofGuard products are a cost-effective fall prevention solution.

All of our rooftop guardrail systems are designed in order to meet or exceed all North American Safety Standards.

With the addition of one of our rooftop fall prevention devices, you will be able to reduce PPE and training requirements of your staff and contractors.

All of our rooftop guardrail systems are safe and reliable fall prevention solutions.

Designed in order to be easily installed, many of our rooftop fall prevention systems can be installed with a single tool.

These fall prevention devices will help protect your employees from injury or death.

With the addition of a rooftop guardrail system, you will be able to reduce the potential for costly fines.

Every single one of the individual components used within these rooftop guardrail systems weighs under 40lbs.

The Hierarchy of Fall Protection Solutions

Elimination of Hazards

- Whenever possible, remove the fall hazard itself.

- If there is no fall hazard, there’s no fall.

Passive Systems

- Do not require the use of Personal Protective Equipment or active participation from the worker.

- Include Guardrails or Netting Systems.

- A preferred choice for its ease of use without the need for additional training and PPE.

Fall Restraint

- Uses personal fall arrest equipment (harness, lanyard, a. anchor point) to stop the user from reaching the edge.

- This type of ttying-offi p the user from falling in the first place.

Fall Arrest

- When all other solutions are infeasible.

- Fall arrest uses the same equipment as fall restraint but the fall protection equipment engages after the fall happens.

- When it engages, the equipment slows the workers descent, bringing them to a safe stop.

Fall Protection Guide

Check to see what federal & provincial regulations for working at heights and fall protection are and which RoofGuard systems help you comply.

Customer Service

Resources

Learn from the experts about safety topics related to working at heights, warehouse safety and ladder safety. Browse our resource library.

Liftsafe Fall Protection

Catalogue

Details about all of our RoofGuard systems can be found in our Liftsafe Fall Protection Catalogue along with safety statistics and other info.

Liftsafe Fall Protection

Supplier of Working at Heights Protection, Aviation Access Products, Netting Safety Systems and Engineering Services across Canada.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.