Work Platform Series

Custom Rooftop Maintenance Platforms with Guardrails for Safe Elevated Access

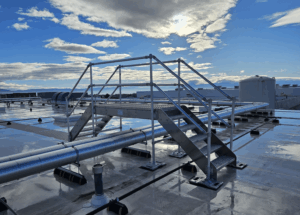

Liftsafe designs, engineers, and fabricates custom rooftop maintenance platforms integrated with RoofGuard guardrail systems to safeguard workers performing tasks at height. These elevated work platforms provide secure, stable access to rooftop equipment while reducing the risk of falls and improving overall maintenance efficiency and productivity.

Our rooftop platforms are fully customized to suit your specific site and operational requirements. Built with modular construction, these platforms are easy to configure, relocate, and expand as needed, making them a flexible and long-term solution. Manufactured using low-maintenance, corrosion-resistant materials, each system is designed with worker safety, accessibility, and performance in mind.

Whether you require single-unit access platforms or complex multi-level systems, all of our rooftop platforms are built to meet or exceed applicable Canadian safety standards, including, including, Ontario Ministry of Labour (MOL), Canadian OHS standards, WorkSafeBC, and ANSI.

Our rooftop maintenance platforms are engineered to integrate seamlessly with your existing rooftop layout and can be customized in various heights and configurations. When combined with our RoofGuard Walkway Series and RoofGuard Guardrail System, you’ll have a comprehensive rooftop safety solution that protects both your personnel and your roof structure.

KEY FEATURES

Easy Installation

Quick to assemble and install on most rooftop types, no specialized tools required

Modular Design

Flexible, reconfigurable system that adapts to nearly any rooftop layout

OHS Compliant

Engineered to meet or exceed Canadian safety regulations, including provincial OHS and WorkSafeBC standards

DESIGNED by Engineers

Custom rooftop safety solutions developed by our experienced in-house engineering team

non-penetrating system

Counterweighted design protects the roof membrane, no drilling required

CORROSION RESISTANT

Constructed from lightweight aluminum for excellent resistance to rust and corrosion

NON-SLIP

Anti-slip stairs and platforms enhance worker safety in all seasons

FULL COVERAGE

Provides site-specific coverage or full and partial perimeter coverage

Talk to a specialist today

Fall Protection Regulations in Canada

| Jurisdiction | Regulation |

|---|---|

| Federal (Canada) | Canada Occupational Safety and Health Regulations, SOR/86-304, Sections 12.01 to 12.09 |

| Ontario |

|

| Quebec |

|

| Alberta | Occupational Health and Safety Code, 2009 Part 9, Fall Protection Sections 138 - 161 |

| British Columbia | Occupational Health and Safety Regulations, B.C. Reg. 296/97 Part 11, Fall Protection, Sections 11.1 to 11.10 |

| Manitoba | Workplace Safety and Health Regulation, Man. Reg. 217/2006 Part 14, Fall Protection, Sections 14.1 to 14.23 |

| New Brunswick | General Regulation -N.B. Reg. 91-191 Part VII, Protective Equipment, Sections 49 - 51 |

| Newfoundland and Labrador | Occupational Health and Safety Regulations, 2012, N.L.R. 5/12 Part X, Fall Protection, Sections 138 to 146 |

| Nova Scotia | Workplace Health and Safety Regulations, N.S. Reg. 52/2013 Part 21, Fall Protection, Sections 21.1 to 21.4 |

| Prince Edward Island | Fall Protection Regulations, EC2004-633 |

| Saskatchewan | Occupational Health and Safety Regulations, 1996, R.R.S., C. O-1.1, R. 1 Sections 102 to 107, and Sections 116 to 116.3 |

| Northwest Territories |

|

| Nunavut | General Safety Regulations, R.R.N.W.T. 1990, c. S-1, Part 7 Sections 104 to 109, and Part 9, Sections 118 to 122 |

| Yukon |

|

Your Perfect Solution Awaits!

Frequently Asked Questions

When is fall protection required?

Employers must provide protection to prevent employees from falling. According to Canadian Centre for Occupational Health and Safety (CCOHS) laws, any surface 3 metres (10 feet) above another level requires fall protection. In most cases, fall protection is required when:

- other means of fall protection are not available or possible, such as guardrails

- working at a height of 3 metres or more (permanent and/or temporary work areas)

- working at a height of less than 3 metres when the surface below could cause a greater injury than just the fall (e.g., machinery; risk of drowning in water or other liquid; open tanks, vats, or pits containing hazardous materials; materials that can shift)

- a worker may fall through an opening in the work surface

- it is determined that fall protection is necessary

I don’t know if I need a rooftop guardrail system. Can Liftsafe Fall Protection help me decide?

For sure! Fall protection regulations can be tricky, so if you’re unsure whether a rooftop guardrail system is the right solution, we can help. Just click here to fill out the form with as much detail as possible and our team will get back to you as soon as possible for a complete consultation. You can also reach our team directly at:

Phone: 1-800-977-2005

Email: info@liftsafegroup.com

Do RoofGuard Guardrail Systems comply with current US/Canada safety regulations?

What is the difference between active and passive fall protection?

Both active and passive fall protection are effective in protecting workers from falling. However, while active protection requires involvement from the worker, passive systems can keep people safe regardless of training level and awareness of a hazard.

Active fall protection are known as Personal Fall Arrest Systems (PFAS), such as body harnesses, lanyards, and anchor points. Passive fall protection, alternatively, are physical barriers or systems, such as guardrails and safety nets, that prevent workers from falling or catch them if they do fall.

Passive solutions are always preferred to active ones. They represent engineering controls that keep people safe regardless of training level and awareness of a hazard.

How can I purchase RoofGuard Guardrail Systems from Liftsafe Fall Protection?

It’s pretty simple. Click here to request a quote and our team will get back to you as soon as possible. Don’t forget to fill out the form with as much detail as possible so we can provide a precise quote. You can also reach our team directly at:

Phone: 1-800-977-2005

Email: info@liftsafegroup.com

How long does it take to install a rooftop guardrail? Does it require any special tools or skills?

Roofguard is incredibly simple to install and can be easily installed by an inexperienced worker with simple hand tools and our instructions. Each system has labels that contain a QR code linking to a series of videos showing exactly how to install it for maximum time savings.

Are RoofGuard Guardrail Systems certified by an engineer?

Each RoofGuard system comes with a stamped engineering drawing back by the in-house engineering team at Liftsafe Fall Protection.

Are guardrails more expensive than horizontal lifeline systems?

While every system is different, at times the initial costs of guardrail can be slightly more compared to horizontal lifeline systems. However, you also need to consider the costs of certifying employees for working at heights (every three years), anchor point inspections (annually), lanyard and harness costs and inspections (annually), recordkeeping (ongoing), a rescue plan, and other related costs. When you take these into account, the overall cost of an installed guardrail system is much lower when compared to horizontal lifeline systems.

There is also the amount of time and resources that must be devoted to making sure these are all adhered to. Whereas, a guardrail system can be set up once and you are instantly compliant.

Are the materials used in the RoofGuard Guardrail Systems protected from corrosion and other environmental factors?

Yes. RoofGuard Guardrail Systems are typically made of aluminum, which ensure durability in diverse weather conditions. They are designed to be protected from corrosion, rust and other environmental factors, and its components contribute to resistance to environmental wear and tear.

How does the RoofGuard Guardrail stay in place if it isn't secured to the roof?

The RoofGuard Guardrail System is a modular, non-penetrating system designed to eliminate the potential hazard of falls over unprotected edges on a rooftop or elevated surface. It is counter weighted, which means it requires no welding, drilling, or bolting into the actual roof structure, and is designed to rest on top of it while still meeting lateral force requirements set out in the appropriate standards and laws.

Can RoofGuard Guardrail Systems be painted?

Yes. RoofGuard comes standard as an aluminum system that is grey but some clients prefer it to be painted safety yellow. This is done in-house with a powder coated paint that is weather resistant.

Can RoofGuard Guardrail Systems be used as an anchor?

No. RoofGuard must not be used as an anchor. This is stated explicitly in the RoofGuard installation manual among other safety requirements.

Can RoofGuard Guardrail Systems be installed on a sloped roof?

Yes. This depends on how steep the slope is for standard systems (it must meet the standards and regulations for sloped roofs). However, custom systems are available for multiple applications including sloped roofs.

PROJECTS

Custom Rooftop Access Solution for Complex Manufacturing Roof Layout

A custom-engineered ballasted stair and crossover stair system was supplied to deliver safe rooftop access and fall protection in accordance with OSHA and ANSI standards.

Safe and Compliant Rooftop Guardrail System for Industrial Food Plant

We delivered a custom rooftop guardrail system that provides permanent fall protection for employees performing regular rooftop maintenance, improving worker safety and supporting safety compliance.

Corrosion-Resistant Stair Replacement for Hazardous Wooden Stair in Cold Storage

We engineered and supplied a custom stair system to safely bridge the roof-to-roof gap. The new non-slip, corrosion-resistant stairs replace the deteriorating wooden structure, improving employee safety while providing a long-term access solution designed to align with applicable safety regulations.

Modular Crossover Stair and Rooftop Stair System for Industrial Safety Facility

We replaced the unsafe wooden ladder with modular aluminum and galvanized steel crossover stairs, providing durable rooftop access that improves employee safety and delivers long-term compliant fall protection.

RELATED PRODUCTS

Roof Walkway Matting

Anti-slip roof walkway matting designed to protect rooftop surfaces and provide safe access for foot traffic.

ROOFTOP GUARDRAIL | ROOFGUARD SERIES

Fall protection systems designed to protect workers performing tasks near rooftop edges.

FALL PROTECTION

SYSTEMS

Full range of fall protection systems created by our in-house engineering team.