Projects

CHALLENGES

- Employee safety

- Regulatory compliance

- Unsafe roof access

- Need for safe access to rooftop machinery

- Quick, modular installation without specialized tools or training

SOLUTION

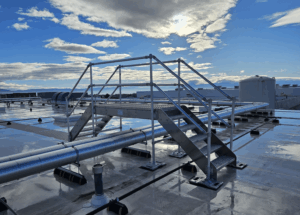

We delivered a combined RoofGuard Classic and HatchGuard guardrail system for a manufacturing facility in Guelph, Ontario, providing comprehensive fall protection for rooftop personnel.

We supplied and installed a RoofGuard Classic free-standing guardrail system around rooftop mechanical equipment, ensuring safe access for maintenance workers. In addition, a HatchGuard kit was installed to protect employees entering and exiting a rooftop hatch. Both systems are non-penetrating, freestanding, and modular, eliminating the need for welding, drilling, or roof penetration while preserving the roof membrane’s integrity.

The HatchGuard system includes a spring-loaded gate that automatically closes, ensuring continuous protection around the hatch opening. Both RoofGuard and HatchGuard provide passive fall protection, allowing workers to safely perform routine rooftop tasks without requiring extra PPE or specialized working at heights training.

We delivered a combined RoofGuard Classic and HatchGuard guardrail system for a manufacturing facility in Guelph, Ontario, providing comprehensive fall protection for rooftop personnel.

Investing in modular, non-penetrating guardrail systems improved worker safety, ensured regulatory compliance, and delivered a long-term solution for rooftop fall prevention.

Related Projects

Learn More about Liftsafe

Let us understand your challenges and help you find the perfect solution for your business.