Netting Safety Systems

Fall-related and struck-by-object workplace accidents are the 2nd and 3rd leading causes of job injuries and fatalities. Every day workers are at risk without adequate equipment, training, and prevention systems in place. Our engineered netting systems have been designed and tested for industrial netting applications that meet all required safety measures to reduce injuries and liability.

Designed and tested specifically for industrial, manufacturing, warehouse, and commercial applications, each solution can be custom designed by our engineering team for any configuration.

RackGuard Netting Systems

Barrier Netting

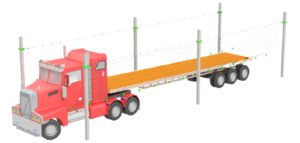

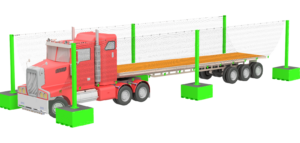

Truck Netting Systems

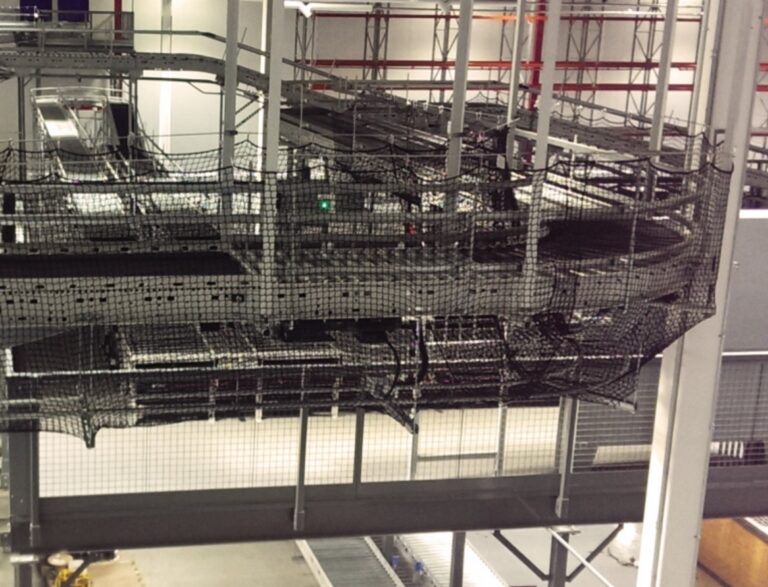

Conveyor Netting

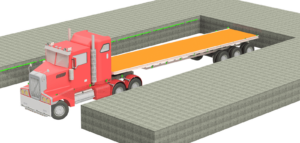

Pit Netting Systems

Construction Netting

Sport Netting Systems

Mezzanine Netting

Your Perfect Solution Awaits!

Why Soft Catch Netting?

Our netting is a soft catch product that absorbs energy as an object falls into it. The system disperses energy from impact point to guard frame, cable, and attachment points. Unlike rigid barriers, our nets are allowed to flex at impact, dissipating energy, and providing less excess force to the netting system itself, keeping your personnel and materials safe.

Engineered Fall Protection Systems

Liftsafe Fall Protection (LFP) has an in-house engineering team that consults with clients to develop customized fall protection systems for unique applications that require it. Passive or active solutions provided.

Industrial Racking Safety Netting System

Conveyor Netting For Distribution Facility

Oil Pit Netting

Installation

Become A Dealer

Offer a wide range of high-quality engineered netting solutions to your customers.

Liftsafe Fall Protection

Details about all of our Netting systems can be found in our Liftsafe Netting Catalogue along with safety statistics and other info.

Liftsafe Fall Protection

Supplier of Working at Heights Protection, Aviation Access Products, Netting Safety Systems and Engineering Services across Canada.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.