Wheel Well and Platform Stands

Keep your crew safe when entering and exiting your aircraft

These Wheel Well and Platform Stands are designed for wheel well and cargo access, for a variety of different aircraft.

As with all our stands, we use anti-fatigue ladder steps rather than narrow ladder rungs. This ensures comfort when using the stands to change LRU’S, adjust components or connect/disconnect engines and nacelles. These stands are currently in use at multiple operators, MRO’S and aircraft manufacturers.

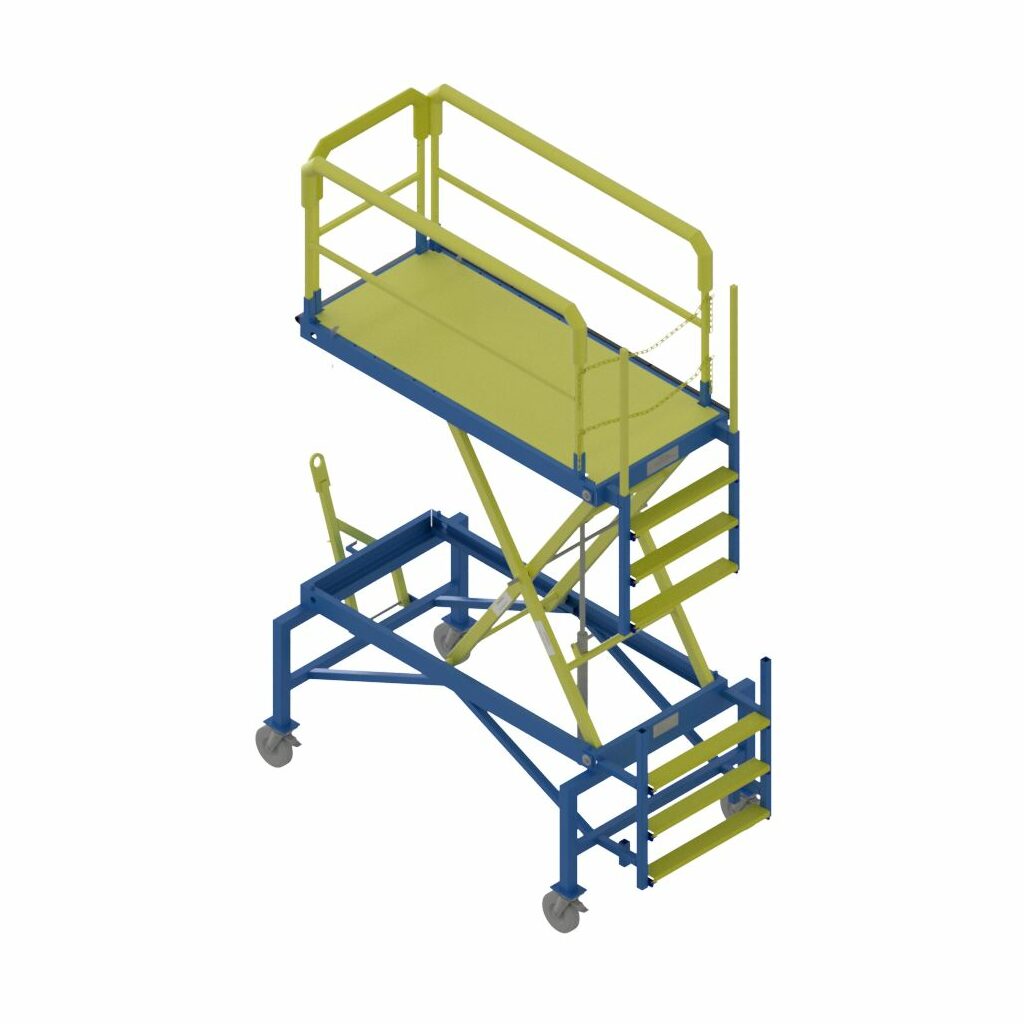

Custom Wheel Well Stands

For:

Wheel Well and Cargo Access

Custom Options Available

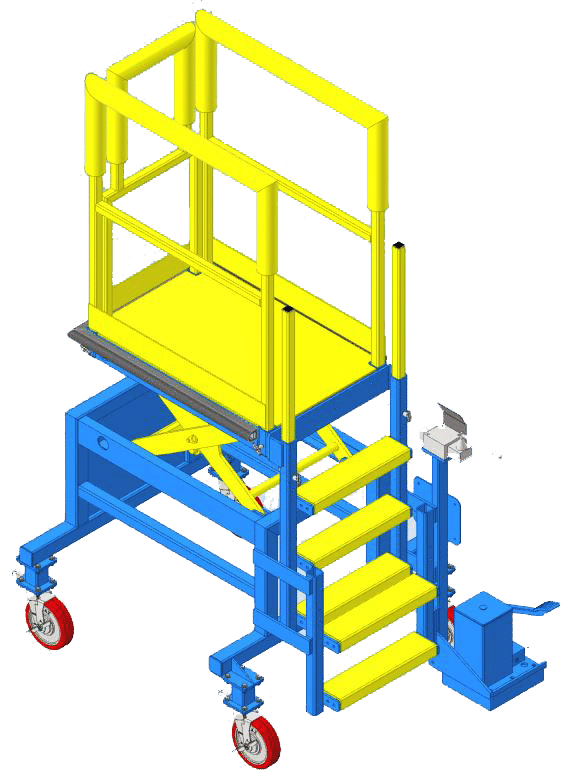

Side Scroll Stand, DF071564-01

For:

Under Cowl & Reverse Thruster Areas

See technical specifications

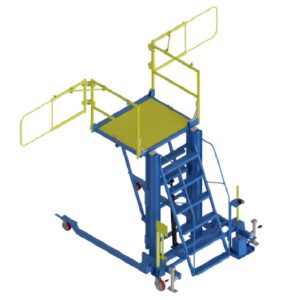

Wheel Well Stand, DF071556-03

For:

Wheel Well and Cargo Access

See technical specifications

Wheel Well Stand, DF071556-03XP

For:

Wheel Well and Cargo Access

See technical specifications

Your Perfect Solution Awaits!

DESIGN

From inception, through to design, fabrication, and installation; Liftsafe Fall Protection (LFP) specializes in standard and custom fixed-wing Wheel Well Access Stands and Ladders. Working alongside our valued clients in the Commercial, Military, and Private Aircraft sectors, we have been recognized as a leader in quality, innovation, dependability and customer service. Our products are designed to safely access maintenance inspection points, perform painting, assembly, overhaul and repairs.

Our specialized solutions allow maintenance personnel to work both safely and efficiently while protecting the aircraft. Our wheel well access products are constructed with premium materials and products in a CWB certified fabrication shop, while exceeding all federal and provincial regulatory requirements including OHSA and ANSI.

Regulatory and Compliance

Our defining philosophy; “safety in the air, starts on the ground”, highlights our core focus of keeping our clients and their teams safe.

All LFP products are engineered, designed, built and tested in accordance with OHSA and ANSI regulations.

Many of our products have also been tested, and meet or exceed BS EN 131.7, DIN EN 12312-8, EN 1915-1, and include CE certifications.

Built for safety and ease of use

Designed to be used to service engines, pylons, radome and AFT fuselage points. Our professional engineers can design custom models based on your specific requirements.

A focus on the finer details

Optional telescopic side rails ensure safety compliant access to the forward and AFT lower cargo holds. The aviation wheel well and platform stands are hydraulically actuated.

Our Process

Phase 1: Design

Simply put, every project is unique. In this phase we will apply a collaborative and consultative approach to define the requirements, to evaluate your needs, and to discuss all possible solutions.

Phase 2: Safety

Our defining philosophy; “safety in the air, starts on the ground”, highlights our core focus of keeping our clients and their teams safe. When developing a solution, our team is committed to providing solutions that incorporate hazard elimination and passive protection into all of our designs.

Phase 3: Compliance

The aviation sector is one of the most heavily regulated industries in the world. Our staff engineers are up to date on the latest safety regulations and ensure that each piece of equipment meets or exceeds safety compliance standards.

Phase 4: Implement

Launching your project with a phased approach that includes manufacturing, commissioning, revisions and training. Each aircraft maintenance project is subjected to the rigors of real world use and adjusted accordingly until it meets all design criteria. Training on best practices and product use is provided.

Phase 5: Support

Once an aircraft maintenance platform makes it from the design studio into the real world, it is subject to real world conditions and usage. That is why LFP offers an ongoing preventative maintenance and service plan to guarantee easy operation and ongoing customer service years after construction.

What our clients are saying

We use them in both the line maintenance and hangar maintenance to accomplish work on the engine and pylons for our wide-body aircraft. These stands are an excellent solution to a longstanding problem - providing fall safety protection in difficult to reach areas. The stands are of high-quality construction and provide a unique solution to a challenging fall safety concern. We would highly recommend this product.

The horizontal lifeline system is user-friendly and provides the additional security for workers that we hoped it would. Those who use it have provided positive feedback. We look forward to working with Liftsafe on future projects.

We would highly recommend this product to any company completing regular maintenance on commercial aircraft engines. We find that Liftsafe is more than willing to work with us in creating safe, economical and multi-purpose designed equipment, tailored to our needs.

About Liftsafe Fall Protection

Customer

Service

Resources and Articles

Browse our resource centre to find manuals, articles, spec sheets, and catalogues to find out more the aviation maintenance systems we carry and the regulations they meet.

Liftsafe Fall Protection

Aviation Maintenance

Liftsafe Fall Protection is a leading supplier of aircraft maintenance products in North America, offering premier fall protection equipment.

About LFP

Supplier of Working at Heights Protection, Aviation Access Products, Netting Safety Systems and Engineering Services across Canada.

About Liftsafe

We focus on creating turnkey solutions that allow your employees to do their jobs safely while protecting your company.